XieHuang Hardware is committed to providing customers with high-quality Tattoo Pen Shell, which is one of the core components of the tattoo machine. It is mainly used to fix the motor, needle group and circuit module. It also needs to have good grip comfort, anti-slip and durability. High-quality tattoo pen shells can not only improve the tattoo artist's operating efficiency and the processing of fine lines, but also ensure the stability and service life of the equipment.

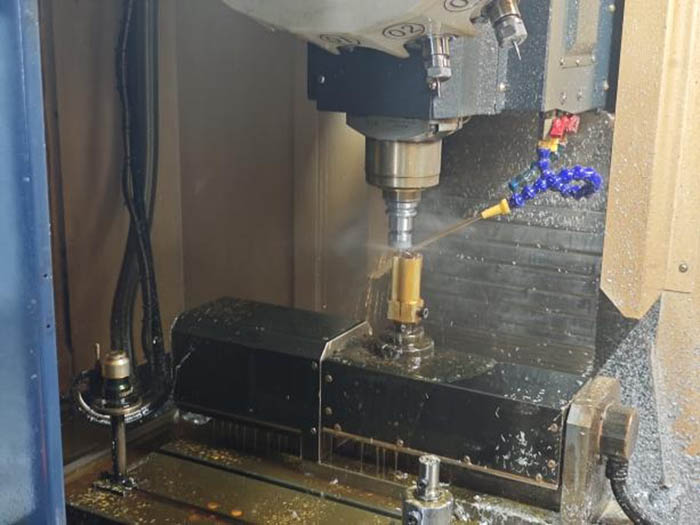

As a professional supplier, you can rest assured to buy this Tattoo Pen Shell from XieHuang Hardware. It has four parts in total. We use aluminum alloy and CNC high-precision processing to ensure the tightness of each part. We also provide customized services according to customers (such as LOGO engraving and color customization).

The appearance of this product adopts engraved anti-slip patterns and hollow structure design, which can reduce fatigue after long-term use, reduce the weight of the whole machine, and reduce the burden on the user's wrist. In addition, our factory also mechanically polishes and deburrs the product, which can eliminate sharp edges and improve the feel.

(Product specifications support customized drawings)

|

Tattoo Pen Shell Parameters |

Standard specifications |

Optional customization |

|

Material |

Aluminum alloy |

Titanium alloy, copper alloy |

|

Size |

Φ33-36mm |

Adjust according to customer needs |

|

Surface Treatment |

Anodized (gray) |

Electroplating/laser engraving/sandblasting |

Customers can customize high-quality Tattoo Pen Shell according to their needs. Our factory will select aluminum bars of appropriate specifications according to product requirements, cut them with CNC sawing machines to ensure the precise size of the blanks, and then perform turning operations, including machining of outer circles, inner holes, and threads (such as syringe interface threads) to ensure concentricity.

The products produced will be inspected by the quality department layer by layer, such as checking key dimensions, surface inspection without scratches, uniform oxide layer, no electroplating shedding, and salt spray test for more than 48 hours.

Features: The integration of the pen shell and the motor housing reduces the assembly process and brings convenience; it can be used in professional tattoo studios and tattoo training schools.

We have a 4,000 square meter modern standard factory building, focusing on the R&D and production of various high-precision Tattoo Pen Shells, providing one-stop services from material selection → CNC processing → surface treatment → assembly testing. Welcome to contact us for free samples or technical consultation!

(3D drawing optimization, DFM analysis and other value-added services can be provided according to customer needs.)