XieHuang Hardwar is a durable CNC Volume Button Metal Hardware Manufacturer. We have been producing various types of volume buttons for 13 years in the industry. So far, we have produced more than 500 models. From material selection to appearance and shape control, to rigorous technical CNC production and oxidation color, to final quality inspection and shipment, we fully meet customer needs. Customer satisfaction with us has reached 99%.

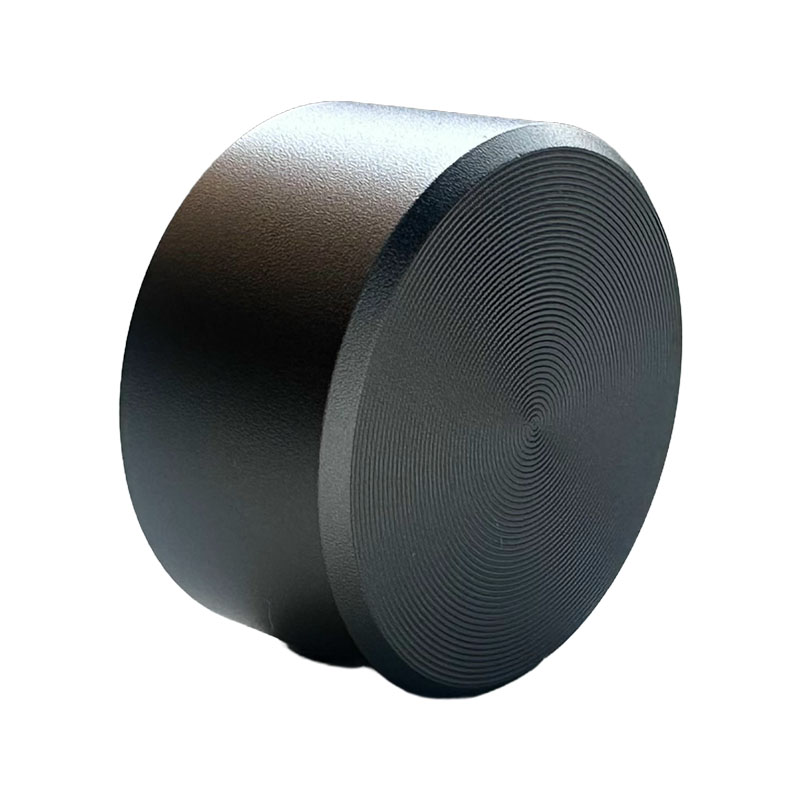

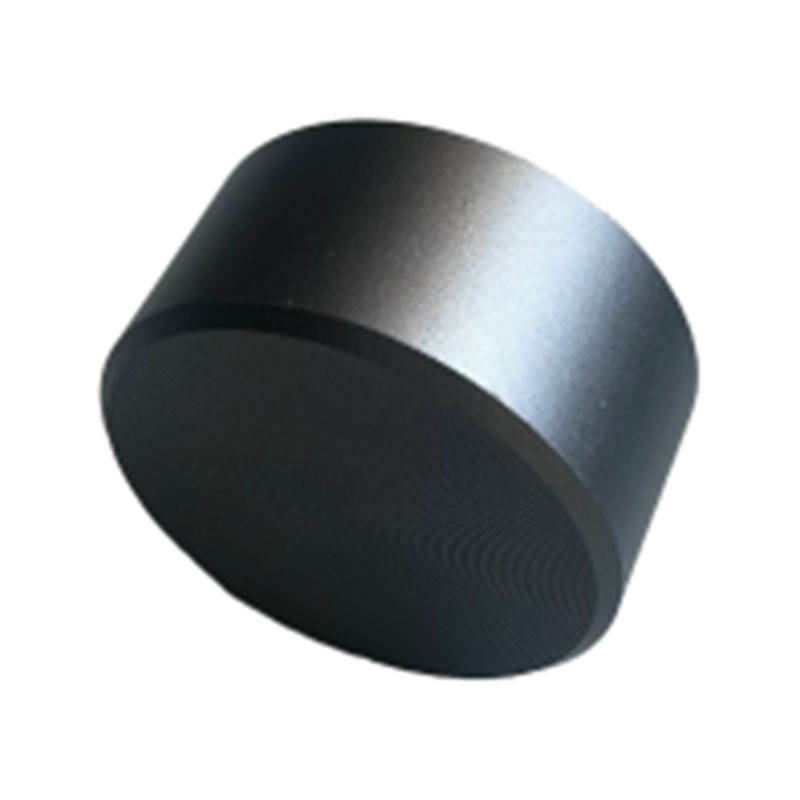

This quality XieHuang Hardware CNC Volume Button has a circular hollow cavity structure and is made of aluminum alloy. Aluminum alloy has a low density of about 2.7g/cm3, is lightweight, easy to process, has high strength, is close to or exceeds some rigidity, has good plasticity, is low cost, and has a high cost performance ratio.

This volume button is made of aluminum alloy material processed and oxidized. Its structure is highly applicable and beautiful. It uses a knob method, which is easy to use and can more accurately control the volume of the sound. It is suitable for various electronic products, such as computers, speakers, headphones, remote controls and other equipment.

We can provide personalized customization services according to customer needs, support a variety of specifications, materials and surface treatment solutions, meet the special needs of different industries, and cover most of the European and American markets. We look forward to becoming your long-term partner in China.

(Product specifications support customized drawings)

|

Parameters |

Standard specifications |

Optional customization |

|

Material |

Aluminum alloy |

Titanium alloy, copper alloy |

|

Dimensions |

Φ22.5mm |

Adjust according to customer needs |

|

Processing method |

Turning, milling |

Adjust according to customer needs |

|

Surface treatment |

Sandblasting oxidation (silver gray) |

Oxidation/electroplating/texture selection |

CNC Volume Button is the latest product developed based on customer drawing requirements, customized in different shapes and sizes. It uses aluminum alloy profiles, and then uses CNC two-axis CNC lathes to turn out its simple shape, and then uses five-axis machines for processing. Then, polishing tools are used to modify the surface of the parts to obtain the required glossiness. Finally, the product is sandblasted and oxidized to the required color.

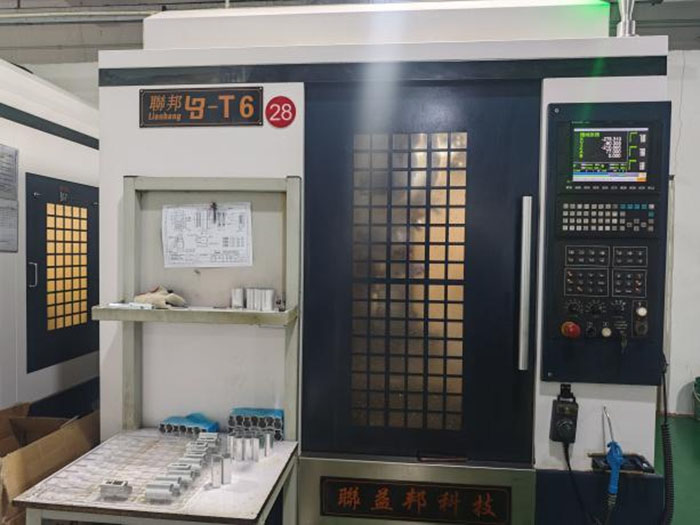

The two-axis CNC lathe is a basic CNC processing equipment with two controllable motion axes. It is mainly used for turning processing (such as shaft and disk parts). It is a simplified version of the CNC lathe and is suitable for small and medium batches and high-precision rotary parts production.

The five-axis machine is the core equipment of high-end CNC processing. It can add two rotation axes on the basis of the three linear axes of X, Y, and Z to achieve high-precision processing of complex curved surface special-shaped parts.

Our factory has been focusing on electronic atomization equipment for 13 years and has passed the quality management system certification. Through material selection, design, processing, surface treatment and quality inspection, we produce efficient and reliable volume buttons to meet the needs of different industries.

Our modern standard factory is equipped with advanced production CNC processing equipment and a professional technical team. We are an enterprise focusing on the production and processing of various hardware products and are committed to providing customers with high-quality, customized hardware product solutions.

Anodized CNC Machining Titanium Parts

Anodized CNC Machining Titanium Parts CNC Machined Parts Anodized Low Volume Titanium Part

CNC Machined Parts Anodized Low Volume Titanium Part Precision Anodized Finished Prototype CNC Machining Parts

Precision Anodized Finished Prototype CNC Machining Parts Mechanical Stainless Steel CNC Machined Parts For Bicycle

Mechanical Stainless Steel CNC Machined Parts For Bicycle High Precision Copper Brass CNC Turned Parts Machining

High Precision Copper Brass CNC Turned Parts Machining Precision CNC Machined Parts CNC Spindle Mount

Precision CNC Machined Parts CNC Spindle Mount